Aerospace Servovalve Test Stands

Servo valve test benches series ValveExpert 8.1.x are used for critical applications which require extremely high precision and specific test conditions. There are versions for mineral oil, Skydrol type media, calibration fluid MIL-PRF-7024, or red oil MIL-H-5606. The servo valve test stands utilise high precision sensors, powerful mathematical tool, simple to use software, low noise & high reliable embedded hydraulic power packs. ValveExpert 8.1.x series test benches are generally used to test, adjust, and repair servo- and proportional valves for aerospace applications. All the stands are equipped with programmable LVDT/LVT electronics to support most known spool position transducers. We collaborate with each customer to meet the requirements.

Industrial Test Equipment for Servo- and Proportional Valves

We manufacture set of precision test benches for servo- and proportional valves used in industry. The most powerful test equipment series ValveExpert 8.2.x is based on our aerospace version. This cost-optimized test equipment is a very power tool for precision analysis without any compromise. A low noise 45.6kW hydraulic power is embedded into the system. ValveExpert 8.2.x is an “plug and play” solution which is generally used to test, adjust and repair servo- and proportional valves. ValveExpert 8.3.x series test stands utilize 68.5kW hydraulic power pack with three servo- motors and are used for high flow proportional valves. This series allow tests at 10…315bar. Pressure compensation system guaranty the specified pressure drop through the valve even in case of a very low supply pressure. The all our test stands can be adopted for your specific needs.

Valve Checker or Portable Tester for Proportional Valves

ValveExpert Checker 2.4 is the latest version of our portable suite case for fast diagnostics of servo- and proportional valves. This valve checker is mainly designed for the control and functional testing of proportional valves with integrated electronics and operating voltage of ±15V or +24V. But it can be also used to control classic servovalves with mechanical feedback. ValveExpert Checker has got advanced set of control modes: -10V. . . +10V, -2V. . . +2V, 0V. . . +10V, -10mA. . . +10mA, -2mA. . . +2mA, 0mA. . . +10mA, 4mA. . . 20mA, 10mA. . . 14mA, -20mA. . . +20mA, and allows diagnostics of the signals from the machine and servovalve under test.

Accessories to Repair Proportional and Servo Valves

Specific tools and accessories to repair and adjust servo- and proportional valves are in our program. We manufacture magnetising devices to adjust ALNICO magnets of servovalves, nozzle adjustment devices to calibrate nozzles of the first stages for nozzle-flapper type of valves, frequency response cylinders to measure dynamic characteristics, hydraulic manifolds and cables for servo- and proportional valves, specific adapters and test connector boxes to simplify calibration of the test equipment ValveExpert.

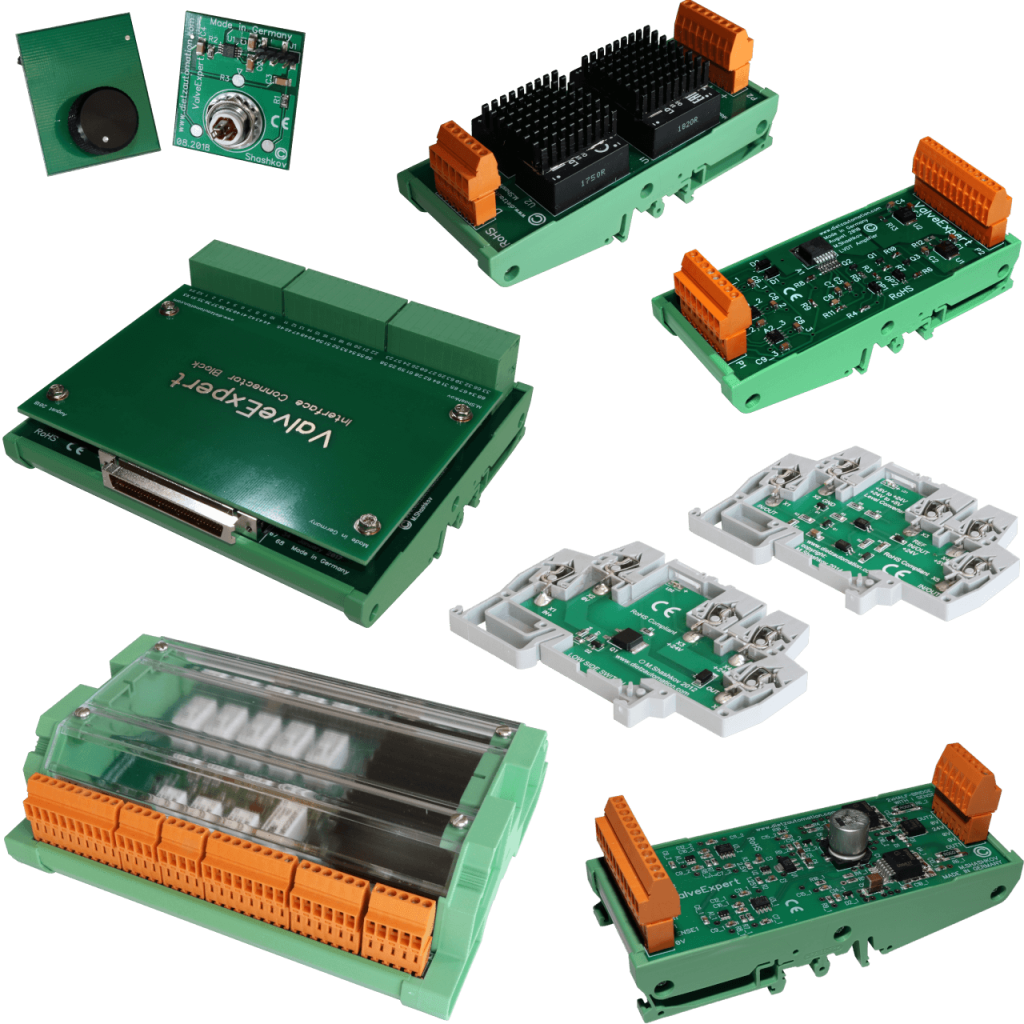

Interface Electronics ValveExpert

Dietz automation GmbH develops and manufacture interface electronics ValveExpert series for the specific needs. Set of electronic cards includes analog and PWM amplifiers to control servo- and proportional valves, level-shifters to interface between low-voltage computer electronics and 24V industrial standard, protected electronic relays to control high current On/Off valves, specific connector blocks, amplifiers for LVDT, rotary position transducers, LED light bars for electric cabinets, LED drivers, and so on. Our electronic cards are extremely robust and do not require any adjustment.

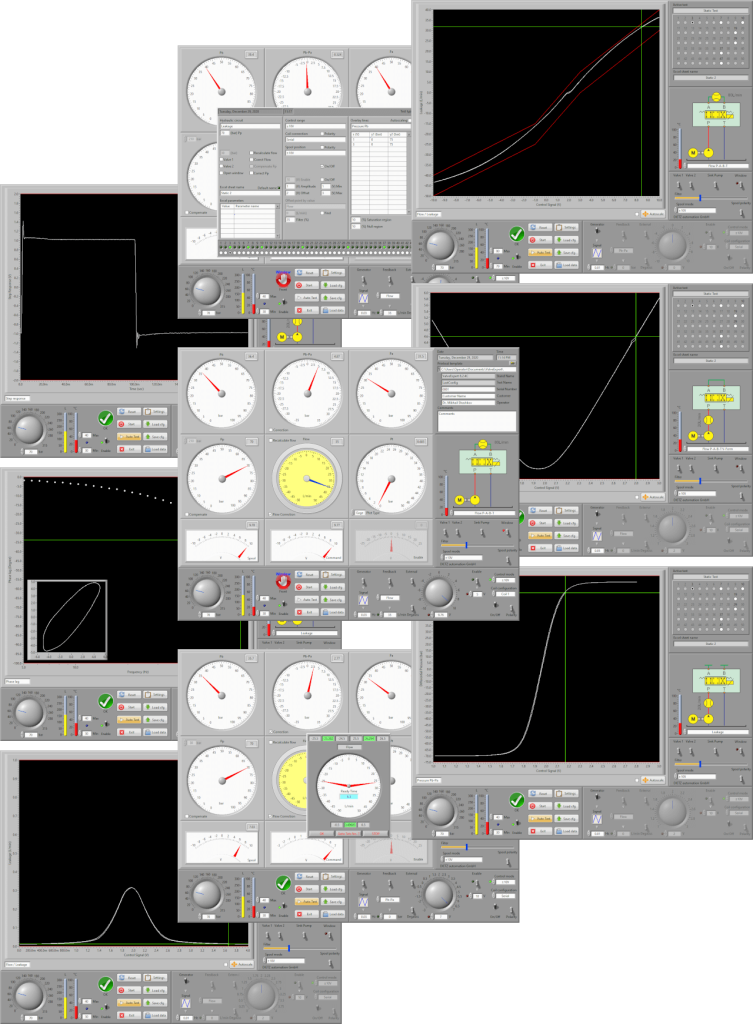

Software ValveExpert

All our hydraulic test stands series ValveExpert have got an intuitively clear software. Operator works with a powerful Virtual Hydraulic Laboratory on a touch-screen monitor. No special knowledges are required. The program ValveExpert has two modes of operation: Manual and Automatic. Hydraulic circuit of the stand can be reconfigured by one mouse click. All the gauges, multimeters, and controls can be simply calibrated and adjusted. Flow prediction system, different pressure compensations, programmable PID regulators and many other tools are built in the software. Extremely powerful mathematical analysis helps to get very precise data and analyse any hydraulic problem your valve. Set of special tools cardinally simplifies the adjustment process. The printout forms of the test results can be simply redesign by customer for each type of valves and meet any specific requirements. Multi-level alarm system protects the operator from risky conditions and informs if service is required.

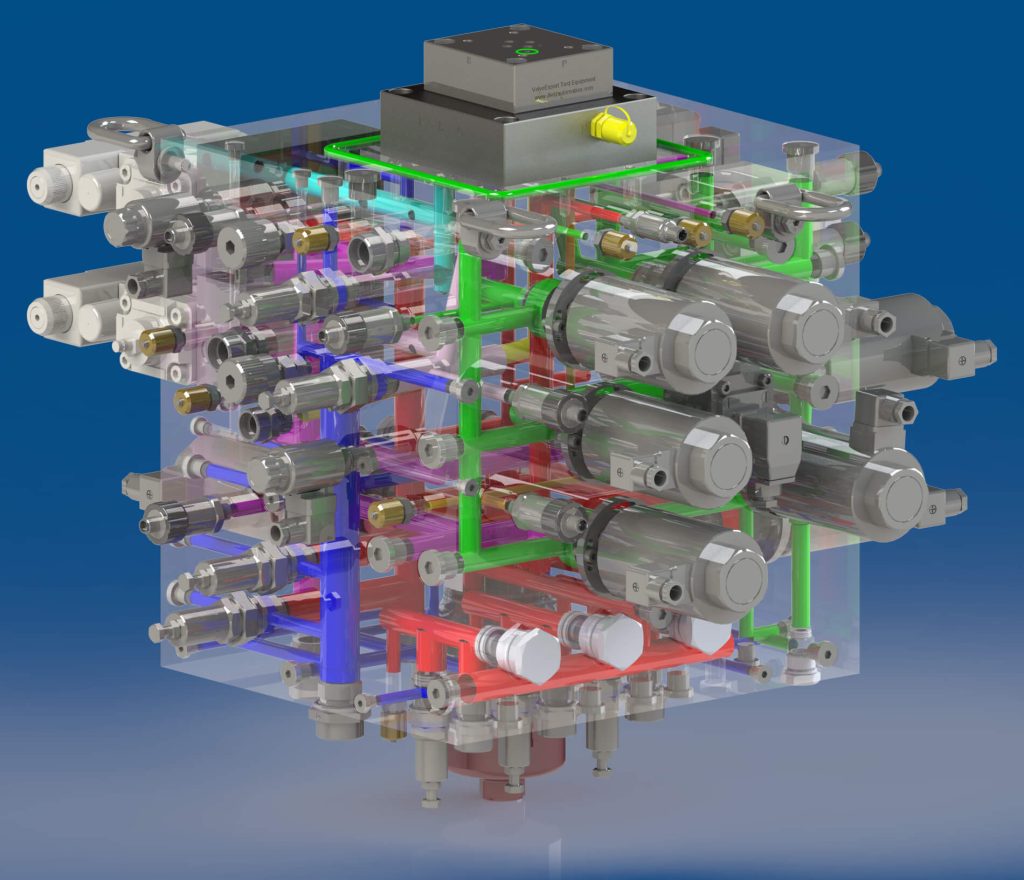

Drawings and Other Documentation

All our test stands are designed with 3D CAD software. We supply detailed information to our customers: 3D drawings, hydraulic and electrical circuits, list of used components and cables, full description of the computer components, I/O cards, and installed programs. Each test stand is supplied with a reserve copy of the software, certificates, calibration data, user manual and others. The picture shows 3D drawings of the main hydraulic manifold ValveExpert 8.1.1.